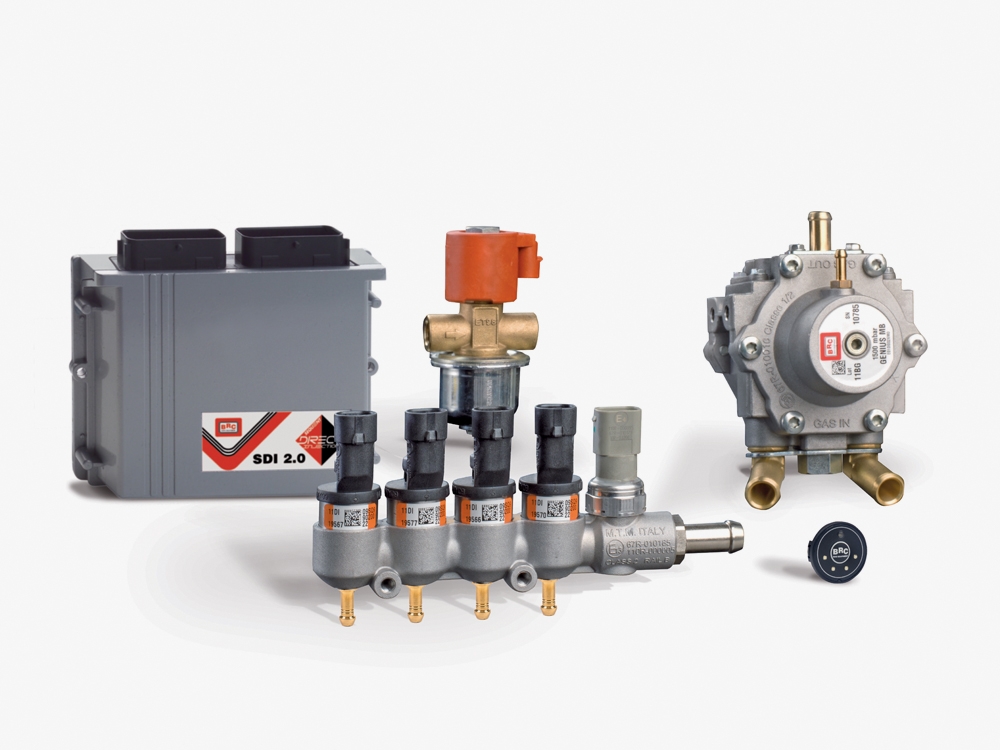

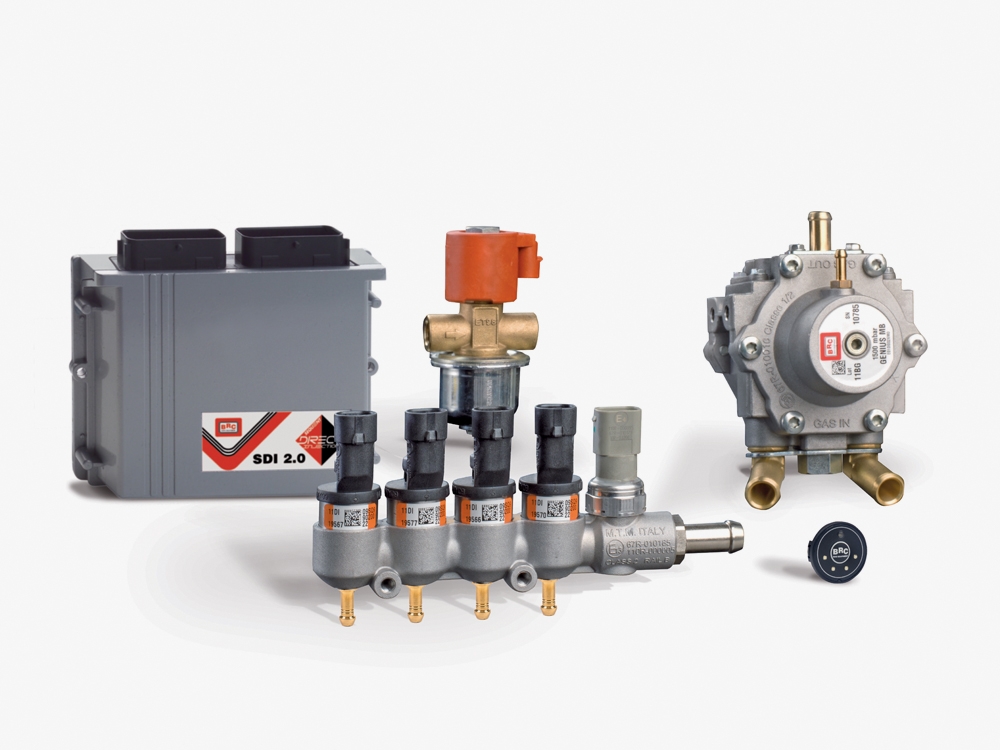

Sequent Direct Injection 2.0

Sequent Direct Injection 2.0

Sequent Direct Injection 2.0 is the system BRC developed for converting to gas the latest generation petrol direct injection vehicles. The gas is injected into the intake manifold while petrol is directly injected into the combustion chamber, allowing to benefit from the easy installation typical of Sequent systems and use the same mechanical parts. Main components include gas ECU with specific software for direct injection management and IN03 electro-injector that accurately manages the injection to increase the gas system performance in terms of both driveability and reliability.

DF Herunterladen Vergleichen Sie

Gaseous phase filter – LPG

• IN and OUT gas fitting ø 12,5 mm

• Cartridge material glass fiber

• Working Pressure 0 ÷ 4,5 bar

• Operating temperature: -40 °C ÷ 120 °C

• Approval: R67-01 and R110

Pressure Gauge – CNG

• CNG pressure sensor

• ø outside 50 mm

• Operating temperature: -40 °C ÷ 120 °C

• Working range 0-260 Bar

• Working voltage from 5 to 10 V

• Connector Tyco Superseal 3 ways

• Fixing M12

• Approval: R110

Genius Max reducer – LPG

• Diaphragm single-stage type building

• Adjusted pressure: 150 kPa relative to the intake manifold pressure

• No bleeding operation needed

• Approval: R67-01

Genius MB reducer – LPG

• Diaphragm single-stage type building

• Adjusted pressure: 800, 1.200 or 1.500 mbar relative to the intake manifold pressure

• No bleeding operation needed

• Approval: R67-01

BRC IN03 MY09 electroinjector LPG/CNG

• Floating shutter with ultra low friction

• Impedance: 1,66 / 1,7 mH a 20 °C

• Temperature: -15°C ÷ 120 °C

• Voltage: 6 V ÷ 16 V

• Seal: Rubber on metal

• Approval: R67-01 and R110

Gas ecu – LPG / CNG

• Automotive microprocessor 16 bit – 64 MHz

• Operating Temperature: -40 °C + 90 °C

• Watertight through immersion

• According to automotive norms for protections and inlet/outlet signals

• Operating voltage: 8 V ÷ 16 V

• Sensors and actuators diagnosis compatible with EOBD

• Communication and reprogramming with PC through K-line

• It supports KWP2000 communication protocol

• It supports CAN 2.0 communication

• EMC compliant

• 2 ECU Versions: up to 6 injectors and up to 8 injectors

• Integrated injectors cut and emulation

• Approval: R67-01, R110 and R10

Zenith reducer – CNG

• Double stage type with diaphragms

• Water Temperature Sensor

• Adjusted pressure: 2.000 mbar relative to the intake manifold pressure

• No bleeding operation needed

• Δp adjustable between 2.000 and 2.500 mbar

• Approval: R110

One Touch changeover switch

• SMD single-stable changeover switch

• ø outside 26 mm

• Possible installations:

– built-in with ø 23 mm hole and 2 mm dimension

• With integrated Acoustic indicator (buzzer)

• N° 4 green Leds for level indication

• N° 1 bi-colour (green/red) Led for mode working indication

PTS Sensata sensor (on rail) low pressure LPG / CNG

• Gas temperature and pressure sensor

• Mass: 22 g

• Overall dimensions: ø= 24 mm, h= 64,5 mm

• Integrated connector

• Power Supply Voltage: 5 ± 0,1 VDC

• Supply Current: 10 mA MAX

• Output Voltage Range (pressure): 0,5 to 4,5 V

• Operating temperature -30 °C ÷ 130 °C

• Approval: R67-01 – R110

Technische Eigenschaften

| Supply | LPG-CNG |

| Cylinders | up to 8 |

| Gas ECU | SDI 2.0 - 56 SDI 2.0 - 154 |

| Gas ECU Connector | FCI 56 Ways TYCO 154 Ways |

| Gas Ecu Body Material | Aluminium |

| Gas Shut-off Solenoid Valves | 2 |

| Reducer - Fittings inlet outlet elbows | LPG Brass and Plastic / CNG Iron |

| Internal Petrol Injectors Emulation | Inductive |

| Gas Temp. Input | ✓ |

| Gas Pressure input | ✓ |

| Water Temperature Sensor on Reducer | ✗ (**) |

| N° Lambda Oxygen Input | 2 |

| RPM Signal | ✓ |

| MAP Sensor | ✗ (**) |

| CNG Internal Timing Advance Processor (*) | ✗ |

| Communication with OBD (K and CAN) | ✓ |

| Sequential Fuel Switch OVER | ✓ |

| Injectors Rail | Aluminium - Plastic |

| Injectors Type | IN03 MY09 |

| Gas Level Indication | Switch |

(*) For using CNG Timing Advance Processors please make reference to respective Sequent systems handbooks

(**) Required only for specific vehicles model