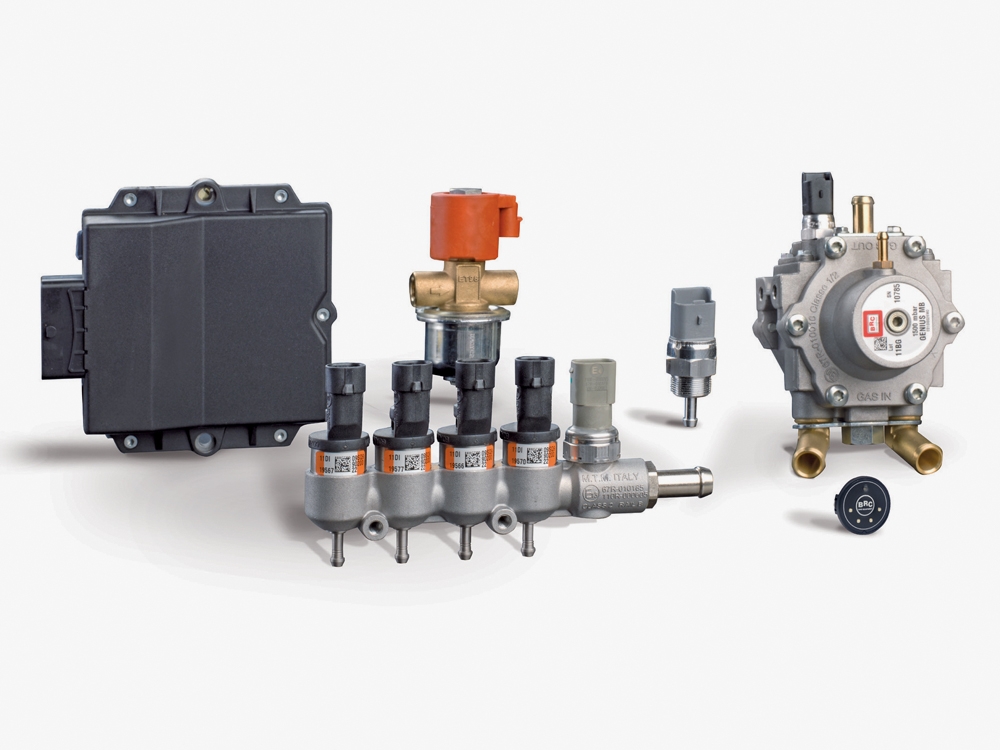

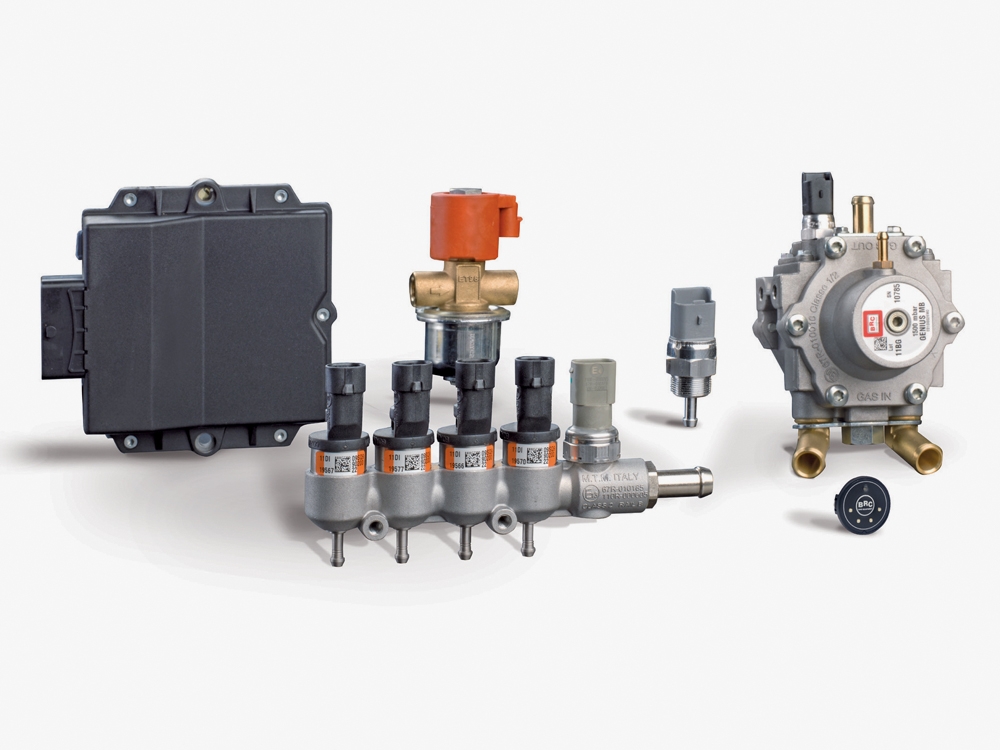

Sequent Plug&Drive MY10

Sequent Plug&Drive MY10

Sequent Plug&Drive is intended for LPG and CNG conversion of 3- and 4-cylinder vehicles. The 64-pin OBD ECU accurately manages the injection through several strategies, considerably improving operation standards. Together with IN03 electro-injectors, the kit Sequent Plug&Drive is top of the BRC systems line.

Descargar PDF Comparar

Gaseous phase filter – LPG

• IN and OUT gas fitting ø 12,5 mm

• Cartridge material glass fiber

• Working Pressure 0 ÷ 4,5 bar

• Operating temperature: -40 °C ÷ 120 °C

• Approval: R67-01 and R110

BRC IN03 MY09 electroinjector LPG/CNG

• Floating shutter with ultra low friction

• Impedance: 1,66 / 1,7 mH a 20 °C

• Temperature: -15°C ÷ 120 °C

• Voltage: 6 V ÷ 16 V

• Seal: Rubber on metal

• Approval: R67-01 and R110

Genius MB reducer – LPG (brass elbows)

• Diaphragm single-stage type building

• Water Temperature Sensor

• Adjusted pressure: 800, 1.200 or 1.500 mbar relative to the intake manifold pressure

• No bleeding operation needed

• Approval: R67-01

Gas ecu – LPG / CNG

• Microprocessor 16bit – 38 MHz

• Operating temperature: -40 °C + 105 °C

• According to automotive norms for protections and inlet/outlet signals

• Operating voltage: 7 V ÷ 17 V

• Max voltage: 24 V

• Sensors/actuators diagnostic compatible with OBD

• Communication Prot. KWP2000 through K-line CAN 2.0

• Aluminium case with plastic cover, totally watertight (IP67)

• Watertight 64-pin connection (IP67)

• Compliant to 2004/104/CE EMC

• Integrated spark advance processor

• It pilots up to 4 injectors

• Integrated injectors cut and emulation

• Approval: R67-01 – R110

BRC IN03 MY09 electroinjector LPG/CNG

• Floating shutter in friction total absence

• Impedance: 1,55 / 1,7 mH a 20 °C

• Temperature: -40 °C ÷ 100 °C

• Voltage: 6 V ÷ 16 V

• Seal: Rubber on metal

• Approval: R67-01 – R110

Zenith reducer – CNG

• Double stage type with diaphragms

• Water Temperature Sensor

• Adjusted pressure: 2.000 mbar relative to the intake manifold pressure

• No bleeding operation needed

• Δp adjustable between 2.000 and 2.500 mbar

• Approval: R110

Map manifold pressure sensor

• Weight: 17 grams

• Overall dimensions: ø= 22 mm, h= 63 mm with pipe-holder

• Pressure Range: 0 ÷ 2,5 bar

• Integrated connector

• Precision 1,5 % F.S.

• Operating temperature -40 °C ÷ 125 °C

• Outlet 0 ÷ 5 V

Genius Max reducer – LPG

• Diaphragm single-stage type building

• Water Temperature Sensor

• Adjusted pressure: 150 kPa relative to the intake manifold pressure

• No bleeding operation needed

• Approval: R67-01

Hp level sensor high pressure – CNG

• Gas pressure sensor

• Weight: 32 g

• Integrated connector

• Power Supply Voltage: 5 ± 0,25 VDC

• Supply Current: 20 mA MAX

• Output Voltage Range (pressure): 0,5 to 4,5 V

• Operating temperature -40 °C ÷ 135 °C

• Approval: R110

MS Zenith reducer – CNG

• Mono stage type with diaphragms

• Adjusted pressure: 2.000 mbar relative to the intake manifold pressure

• No bleeding operation needed

• Approval: R110

One Touch changeover switch

• SMD single-stable changeover switch

• ø outside 26 mm

• Possible installations:

– built-in with ø 23 mm hole and 2 mm dimension

• With integrated Acoustic indicator (buzzer)

• N° 4 green Leds for level indication

• N° 1 bi-colour (green/red) Led for mode working indication

PTS Sensata sensor (on rail) low pressure LPG / CNG

• Gas temperature and pressure sensor

• Mass: 22 g

• Overall dimensions: ø= 24 mm, h= 64,5 mm

• Integrated connector

• Power Supply Voltage: 5 ± 0,1 VDC

• Supply Current: 10 mA MAX

• Output Voltage Range (pressure): 0,5 to 4,5 V

• Operating temperature -30 °C ÷ 130 °C

• Approval: R67-01 – R110

Características técnicas

| Supply | LPG-CNG |

| Cylinders | ≤ 4 |

| Gas ECU | Sequent P&D MY10 |

| Gas ECU Connector | FCI 64 Ways |

| Gas Ecu Body Material | Aluminium / Plastic |

| Gas Shut-off Solenoid Valves | 2 |

| Reducer - Fittings inlet outlet elbows | Brass |

| Internal Petrol Injectors Emulation | Resistive |

| Gas Temp. Input | ✓ |

| Gas Pressure Input | ✓ |

| Water Temperature Sensor on Reducer | ✓ |

| N° Lambda Oxygen Input | 1 |

| RPM Signal | ✓ |

| MAP Sensor | Included |

| CNG Internal Timing Advance Processor (*) | ✓ |

| Communication with OBD (K and CAN) | ✓ |

| Sequential Fuel Switch OVER | ✓ |

| Injectors Rail | Aluminium |

| Injectors Type | IN03 MY09 |

| Gas Level Indication | Switch |

(*) For using CNG Timing Advance Processors please make reference to respective Sequent systems handbooks

(**) Required only for specific vehicles model